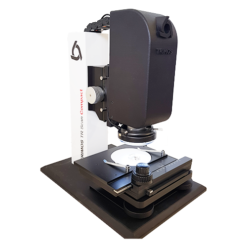

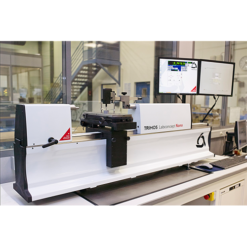

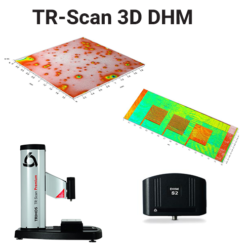

Trimos Optical Measurement with [TR Scan Compact with WLI sensors]

TR SCAN COMPACT WLI

HIGH PRECISION NON-CONTACT SURFACE MEASUREMENT

The new TR Scan Compact WLI range allows measurements on any type of material with sub-nanometric resolution.

With its simplicity of use and small size it integrates easily in a lab environment and permit to realize quick and simple measurements.

- Non-contact

- Small footprint

- Measuring range 400 µm

- Resolution 0.1 nanometer

- Extremely easy to use

- 2.5x and 5x Michelson type optics for a wide field of view

- Exchangeable optics, or mounted on a carousel