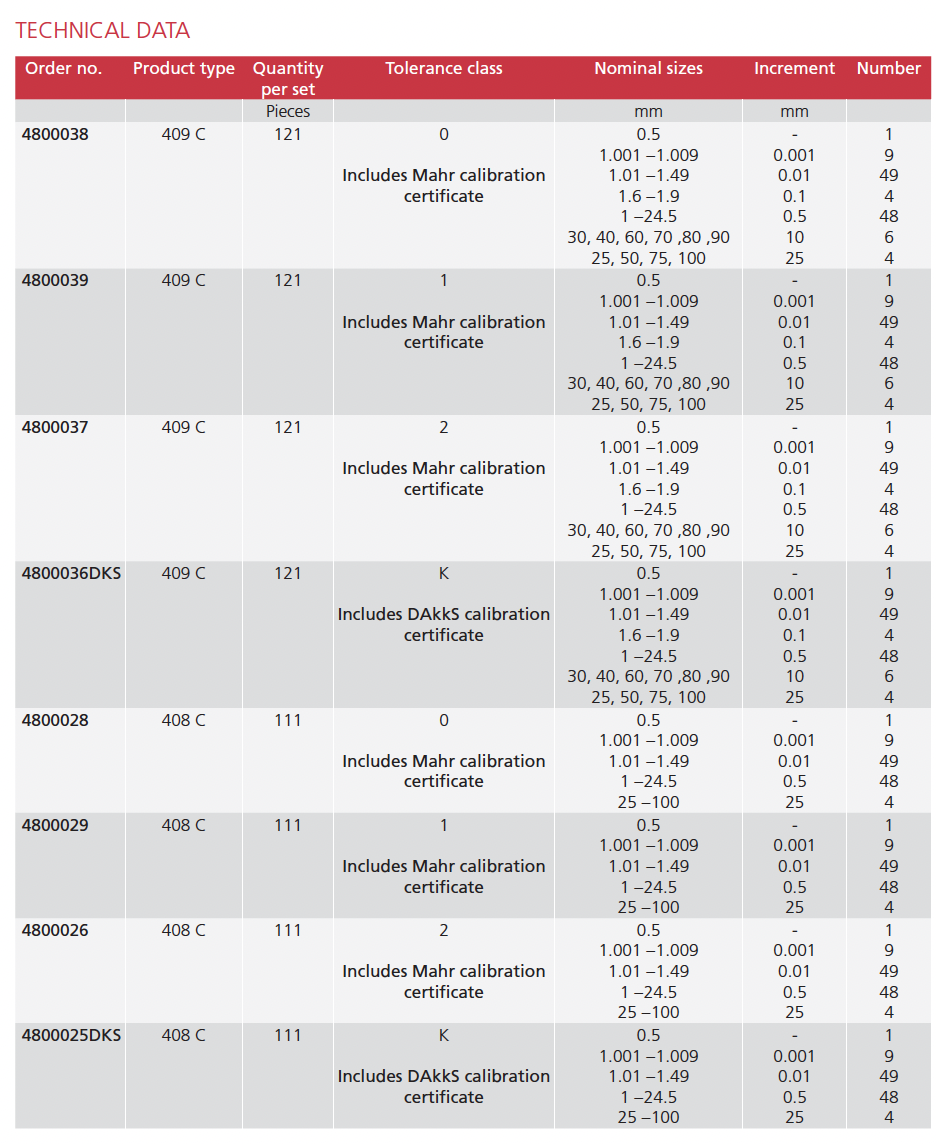

MarGage 409 C / 408 C | Rectangular Gage Block Set made of Ceramic

FEATURES

Advantages of ceramic:

• Resistant to impact and breakage. Damage to measuring surfaces from scratches or to edges from impact causes minimal burring. Sliding ability is retained for longer

• Extremely wear-resistant. The longest life and highest stability of any material currently used in measuring technology. Allows for significantly longer gage monitoring intervals

• Corrosion-resistant. Circonimar is extremely resistant to alkalis, acids, oil, grinding fluid and other aggressive media even without protective measures

• Coefficient of expansion similar to that of steel. Therefore there are no usage restrictions, even in extreme temperature conditions

• Circonimar is non-magnetizable, anti-static, anti-magnetic and non-conductive. It does not attract dust or dirt.

Calibration class K

As primary factory standard, particularly for the calibration of subsidiary test laboratories, e.g. for gage blocks of lower tolerance classes.

Tolerance class 0

For maximum accuracy requirements. To be used as basic standards in test laboratories and precision inspection rooms, where other gage blocks and high accuracy measuring instruments are calibrated.

Tolerance class 1

For high accuracy requirements. As reference gage block for the measuring room. Designed to perform particularly accurate measurements. For setting indicating measuring instruments. For checking precision gages.

Tolerance class 2

For checking production gages of quality IT 6 and IT 7. For setting indicating measuring instruments and for checking accurate dimensions in the jig and tool industry.

• Package contains: wooden case with clear labeling strips, Mahr calibration certificate

• Coefficient of linear expansion: 9.3 x 10–6 K–1