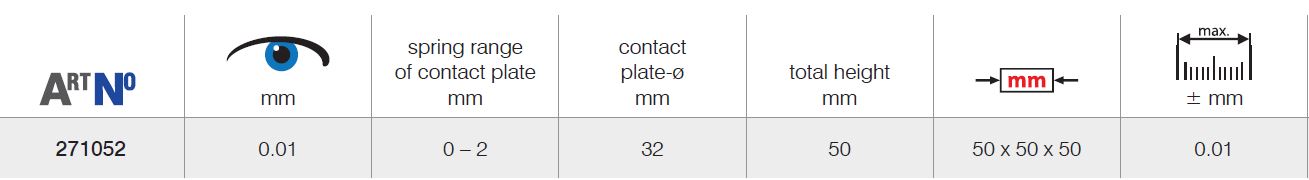

Zero Setter with permanent magnetic base

• to adjust the tools, for example milling tools, to the „0“-position and for

to determine the reference point of the machine spindle

• no feeler gauge or starting contact is needed

• no damages at the measuring element and at the work piece

Operational instruction:

• calibrate the zero setter by putting a parallel on the setter and press it against

on the spring loaded surface and set the dial gauge at „0“

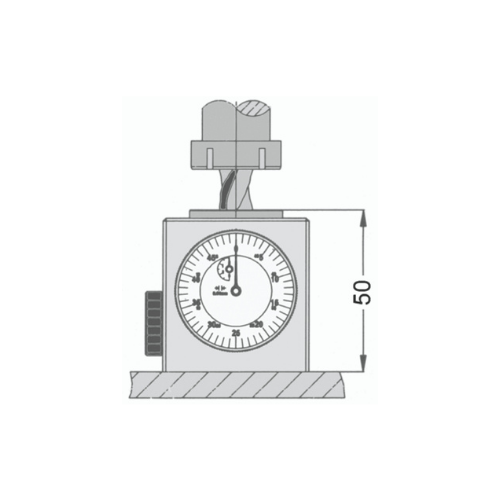

• put the setter on machine table or workpiece reference surface.

Move spindle to bring cutting tool to touch measuring surface and read

• the dial gauge carefully. When the dial points are at „0“,

the distance between tool end and machine table is 50 mm (±0.01 mm)