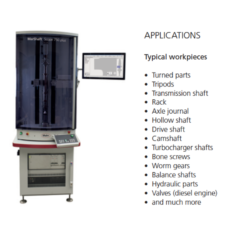

MarShaft MAN | OMS 120 optical Measuring System

DESCRIPTION

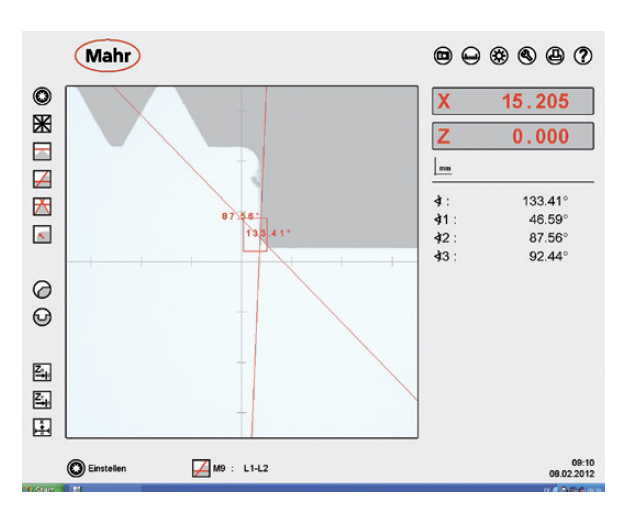

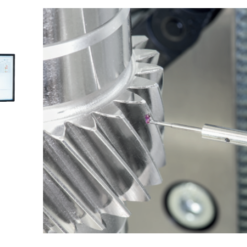

• In conjunction with the evaluation software, the optical measuring system OMS 120 can be used to measure geometry elements which cannot be contacted or evaluated with the available contacting measuring probes of MarShaft MAN. The operating concept is optimized for use directly on the production line and can be used without any knowledge of metrology whatsoever. The testpiece contour is mapped on the camera chip using the shadow image method and displayed on the monitor. High-quality, telecentric optical components are used for precision mapping. To this end the corresponding testpiece contour is positioned only roughly in the camera’s image field. There is no need for precision adjustment in the Z or X direction. The software has quick measuring functions which automatically evaluate the relevant feature results for the current measuring task.

Quick measuring functions

• Recess

• Chamfer

• Radius

• Straight line

• Intersection point line-line A quick measuring function analyses multiple feature results at the same time. The relevant results can be selected for recording or for data transfer. Most shaft measuring tasks can be performed in a quick and user-friendly manner using these functions.

• A whole range of manual analysis functions are available for measuring tasks which are not covered by the quick measuring functions.

Technical data

• Traverse path in X-direction: 120 mm

• Measurement resolution: 0.001 mm